Decided to actually pull the back of the car out of the garage to double-check the valves and torque down the lower part of the heads to see if that was causing my low compression reading on cylinder #3. I realized when I tried to check the valves on Thursday night that I had the engine in the complete wrong position. For some reason I hadn’t been able to see the notch in the distributor that signified cylinder #1. I left Thursday night thinking I had done something very wrong, and a couple people on the Type 3 list mentioned that I must have had the engine turned 360 degrees incorrectly if I couldn’t adjust the valves. That’s exactly what had happened. So I turned the engine over to where it should be for cylinder #3 and took the valve cover off, removed the rocker arms and checked the torque on the heads. They were way loose and I was hoping this was my problem. Put the rocker arms back on, torqued them up, did a complete valve adjustment, then did the compression test. I gained 10psi on cylinder #3, but that still only brought it to 60psi, which means either way I’m going to have to pull the engine out. Decided *not* to do that today. Instead, I jacked up the front of the car to get a good look at the underneath of the gas tank & to replace the fuel lines in the front. I discovered a little canister on the front of the torsion bar beam and didn’t know what it was. It went to the pressure outlet of the fuel pump and then to a line in the tunnel. A few posts on the Type 3 list noted that this was a “fuel muffler,” and that most cars either had it removed by now, or could have it removed. I decided to leave it on though and replaced its fuel hoses. The only one I did not do was the one from the three-way plastic plug to the tank itself. I was going to put a long hose on that one so the tank would be easier to take out if and when necessary, but Jim Adney suggested that I leave the tank because it’s tough to seal it up sometimes after you get it out. I’m leaving it. I took the fuel pump with me because I wanted to take it apart, but knowing how much it costs, I think I’ll leave the taking apart for when I have some more cash (or until I it actually fails) in case I futz it up. I do need to get at least one new mounting bracket for the pump though, as it looks like the rubber sheared off from the clamp that holds the pump. The pump was just kind of “resting” on the bushing. Also replaced the fuel filter as well.

April 16, 2003

Another beautiful night last night, and my wife was in Manhattan with my stepson attending an open house at a school for holistic medicine, so I figured I’d stop by the car on my way home & finally do the compression check. Got all the plugs out and screwed in the plug for the tester. Took all the wires off the distributor cap as I needed to sort out the order anyway, and I have a new set coming from Aircooled.net. Got in the car, turned the key for a couple seconds & went back to take a look at the gauge. 120psi. Much better than I had hoped for. Took the hose and adapter out of cylinder 2 and did cylinder 1. 128psi. Nice. Got to cylinder 3. 50psi. Yipes. Did cylinder 4, 120psi and then went back to cylinder 3 to check it again. Again, 50psi. Not good. At this point I was thinking it was most likely valve related, as I didn’t think the rings could be that far gone on only one cylinder. It started raining so I packed up & went home, trying to figure out what to do next. A couple people on the Type3 list said I should check my valve adjustment (will do that tonight or Saturday) and Russ mentioned that there’s a chance that a piece of carbon might be caught in the valve keeping it from sealing shut.

April 15, 2003

I had grand ambitions tonight, but ended up doing just a few things. I was glad to see the battery was still fine and that I didn’t have any mysterious drainage from anything. However, I realized the clock actually didn’t work. It ticks, but it doesn’t keep time. Not a priority in any case. As recommended by Jim Adney off the type 3 list, I checked the starter terminal connections to see if they were mixed up, as that could be causing the problem where I don’t hear the fuel pump relay clicking off after a second or two of the ignition being on and the car not starting. Wires were on the correct terminals but there was a lot of corrosion on the red/white terminal. Cleaned it off a bit and wondered why there wasn’t a plastic boot on it to protect it from the elements. I had been wanting to check the trigger points in the distributor, so I finally loosened the adjustment screw and got the distributor out. Pulled out the trigger points module and everything in there was very clean. I took whatever little gunk was off the plastic tabs that hit the distributor cam lobes, put just a dab of lube on the cam and put the points back in. Sometime during this operation, a couple plug wires came off the distributor cap. Damn. Decided to order a new set & just make sure everything is rewired properly when I put the new wire set on. Old ones were questionable anyway.

I had grand ambitions tonight, but ended up doing just a few things. I was glad to see the battery was still fine and that I didn’t have any mysterious drainage from anything. However, I realized the clock actually didn’t work. It ticks, but it doesn’t keep time. Not a priority in any case. As recommended by Jim Adney off the type 3 list, I checked the starter terminal connections to see if they were mixed up, as that could be causing the problem where I don’t hear the fuel pump relay clicking off after a second or two of the ignition being on and the car not starting. Wires were on the correct terminals but there was a lot of corrosion on the red/white terminal. Cleaned it off a bit and wondered why there wasn’t a plastic boot on it to protect it from the elements. I had been wanting to check the trigger points in the distributor, so I finally loosened the adjustment screw and got the distributor out. Pulled out the trigger points module and everything in there was very clean. I took whatever little gunk was off the plastic tabs that hit the distributor cam lobes, put just a dab of lube on the cam and put the points back in. Sometime during this operation, a couple plug wires came off the distributor cap. Damn. Decided to order a new set & just make sure everything is rewired properly when I put the new wire set on. Old ones were questionable anyway.

Also, in my first most embarrassing moment, I realized that the gas tank is most likely empty. The Muir book says to watch out for this, but did I pay attention to that? Nope. Turned the key and for the first time watched the gas gauge go… NOWHERE. Got out and pushed on the side of the car with the hood open to see if I could hear any sloshing. Nothing. I figure now would be a good time to change all my fuel lines. I’ll take care of that Saturday before putting any gasoline in the tank. It probably might not be a bad idea to check the status of the tank as well. Listened to a little bit of the Bruins game 4 on the Wolfsburg radio. Sweet.

April 12, 2003

Vacuumed out the baking soda I had left covering the battery area as well as the other side of the rear seat. I noticed that there was a yellow with red stripe wire that had been taped off with electrical tape coming from the positive side of the battery connection. I looked it up in the Bentley manual wiring diagram and I believe it just went to the computer connection that VW used to check the engine and electrical system. It was probably used to check the condition of the battery. Looked like it would’ve connected to an older stock battery?

Vacuumed out the baking soda I had left covering the battery area as well as the other side of the rear seat. I noticed that there was a yellow with red stripe wire that had been taped off with electrical tape coming from the positive side of the battery connection. I looked it up in the Bentley manual wiring diagram and I believe it just went to the computer connection that VW used to check the engine and electrical system. It was probably used to check the condition of the battery. Looked like it would’ve connected to an older stock battery?

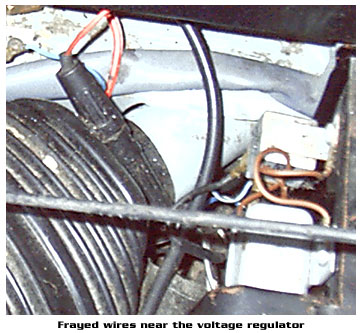

Anyway, I also found by the voltage regulator on the other side that several wires were frayed and uncovered. It looked like someone had tried to splice them together and didn’t do a very good job at it. I don’t think I have any leeway in cutting them down and resplicing them though because they’re in there pretty tight and it’s a hard place to get at. I’ll have to find out what each connection is for and then figure out if it’s causing the car not to start, or if it will provide problems later on. Could very well be a ground to something. Interestingly enough, this battery is shorter than the one I pulled out and has a positive terminal cap to prevent shorting out on the seat springs. The Interstate battery it replaced did not have a cover and was most likely tall enough to hit the seat springs. Wonder what kind of hell that could’ve caused?

After the battery was in, I replaced the points (heavily pitted) and condenser, set the point gap, lubed the distributor cam and popped the cap back on. Decided to see if the pitted points were stopping the engine from running. Turned on the ignition and nothing but the first “click” and the hum of something in back of me (fuel pressuring up?). Also, the oil and generator lights went on. Turned on radio. It worked. Horn worked too. Before I started suspecting a starter problem, I took the car out of park and put it into neutral, then tried again. Car turned over, but didn’t start. OK, so much for me taking the lazy way out. Changed the spark plugs and was VERY happy I had picked up one of those double-jointed elbow sockets on the way over because it made the job not only easier, but possible.

Plugs were covered in soot, but were not oily. Engine must have been running rich, but my previous thought that the compression might be bad might not have been entirely accurate as there was no sign of oil on the plugs. Of course, the one thing I was supposed to get on the way over — a compression tester — was the one thing I totally forgot about when I stopped at Pep Boys. I did pick up one of those lighted telescoping magnets though, which came in infinitely handy when trying to put the condenser hold-down screw in. Another weird thing — the new condenser goes in upside-down. Only way I could get it in, and the way the new bracket is attached it looks like it’s meant to be that way.

Lost the rubber gasket from inside my spark plug socket on #3 cylinder. Popped it off the plug but it’s now stuck under the engine tin. I couldn’t get to it with my fingers, but I’ll have to try again tomorrow when I go back to do some fuel injection troubleshooting. Didn’t put any anti-seize on the plug threads either, which I don’t necessarily think is a bad thing. Aircooled.net says use milk of magnesia, but I had none available, so I put them in dry. Looks like the old ones were put in dry as well, so I’m not worried.

Tried to start the engine quickly again, and no dice. I know the type3 list talks about two clicks you should hear from the fuel injection system — one when you turn the key, then another one a second or two later. I don’t hear the second one. Will have to find out what the second one is for. Looked through the Muir book when I got home and found out it has a pretty decent troubleshooting section on getting the Type3 FI engine started. I guess I’ll start going over that from start to finish — going to set the valves, then check for spark & fuel & all the stuff it suggests. I am a bit worried that Muir says 100K is the top of the life expectancy of this engine, but hopefully when I do finally get a compression tester on it the results won’t be horrible.

Discovered the timing marks on the crank pulley are for 0, 5, 7.5 and 10 degrees BTDC. Static timing is set to 0 degrees, but the Bentley says timing should be set with a strobe, so I’ll do that after I get the engine running. Zero degrees should be good to start with I think. Also realized that the gas tank filler door does not open. Guess I’ll have to find a way around that. So I guess the goal right now is to get the engine started. Once it starts, I’ll get to replacing fuel lines and other stuff before it’s actually driven anywhere. I’m trying not to let anything else distract me too much.

April 10, 2003

Dropped off the new battery and wanted to get the distributor out so I could bring it home and change the points & condenser. Tried to pull the engine lid up and ripped the cord that lets it hang from the roof lip. Wonderful. Bentley manual said it you just unscrew the bracket on the distributor and lift it up. EERNT! The bottom of the bracket was hitting a bar running lengthwise across the engine. A quick post to the type 3 list and I found out this bar is for the warm-up flaps and that I’ll have to find a way to unscrew that part of the bracket. I have no idea how to get to it really. Guess I’ll wait until Saturday when I have time to get to the car and it’ll be a little warmer.

Dropped off the new battery and wanted to get the distributor out so I could bring it home and change the points & condenser. Tried to pull the engine lid up and ripped the cord that lets it hang from the roof lip. Wonderful. Bentley manual said it you just unscrew the bracket on the distributor and lift it up. EERNT! The bottom of the bracket was hitting a bar running lengthwise across the engine. A quick post to the type 3 list and I found out this bar is for the warm-up flaps and that I’ll have to find a way to unscrew that part of the bracket. I have no idea how to get to it really. Guess I’ll wait until Saturday when I have time to get to the car and it’ll be a little warmer.

Put three vanillaroma trees in the car to get the musty smell out. Eventually I want to wash the carpets with foam cleaner I picked up. Hopefully that will solve the problem for good. Also dropped off the fire extinguisher as well. Found out that the flourescent work light I got puts out a lot of light. Hangs real nice off the back of the roof lip as well (where the damn strap was supposed to go). Accidentally unclipped two spark plug wires from the distributor cap during all this, both on the same side. I’ll look back at the pictures I took to see what was what. Found another electrical clip that was off as well — next to what I presume is the kickdown switch. Man, I have no idea how tough it’s going to be to get the spark plugs out. Looks even tougher than my old beetle. Took the cover off the generator belt pulley to see if I could locate the timing marks on the main pulley.

One thing that worries me, since I haven’t yet done a compression check on the engine… I was able to turn the pulley REAL easily. I recall maybe it was the Bentley manual that said don’t put your plugs back in until you do your valve job because it’ll make the engine harder to turn if you do. It seemed like I got no resistance on the pulley at all. Guess I have to pick up a compression tester & check that out. The pulley was marked real nicely. Will look in the Bentley to see what they are. I figure 5 degrees before, then 5, 7.5 & 10? There were four marks. Plan to hook up the battery Saturday & change the oil, do the Bentley tune-up & then see if it will start. If it does, I’ll move onto the brakes & see if putting fluid in the system is all it needs. I have hoses, shoes, clips & one caliper rebuild kit on order in case I need them. Got pads on e-bay a couple weeks ago real cheap. At some point I’ll hook up the VW fuel injection tester & see if everything is good on that front. I’ve heard nightmare stories about the FI harness, but I’m hoping for the best.

Sat in the driver’s seat for a few minutes. The guys on the list are right — brake pedal is going to be a pain at the beginning. Got back in the Jetta and realized I have really gotten used to having a lot of legroom. Can’t wait until Saturday.